Dosing disk level adjusting switch.

Dosing disk level adjusting switch.

Model no. |

ACF-120 |

|

Capacity (caps/hr) |

67,000 ~ 84,000 |

|

Capsule Size |

#00, #0, #1 ~ #4 |

|

Power Supply |

220/380 V, 3 Phase, 50/60 Hz |

|

Power Consumption |

17.2 A |

|

Main drive |

2

HP |

|

Auger drice |

1/2

HP |

|

Vacuum Pump |

2 HP |

|

De-duster |

3 HP*2 PCS |

|

Machine Weight |

1,300 KGs |

|

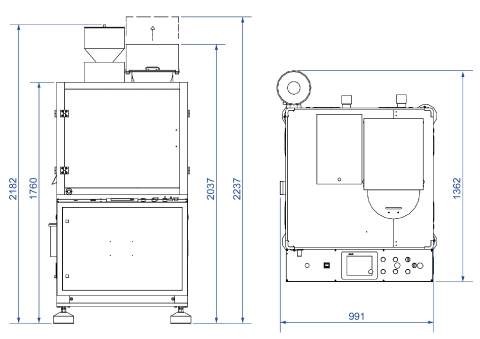

Dimension |

983×1,201×2,013 mm (L×W×H) |

|