Dosing disk level adjusting switch.

Dosing disk level adjusting switch.

|

Capacity

|

120,000

/ hr

|

|

|

Capsule

Size

|

#00,

#0, #1, #2, #3, #4, #5

|

|

|

Power

supply

|

220/380V

, 3 PHASE , 50/60Hz

(For customer to designate) |

|

|

Power

Consumption

|

220

V 12A

380 V 6.6A |

|

|

Main

Drive

|

2

HP

|

|

|

Auger

Drive

|

1/2

HP

|

|

|

Vacuum

Pump

|

1-

1/2 HP

|

|

|

Net

Weight

|

1,530

KGs

|

|

|

Cross

Weight

|

1,750

KGs

|

|

|

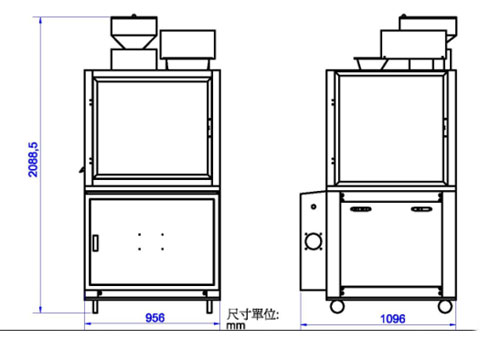

Dimensions

|

956

x 1096 x 2,030 mm (L x W x H)

|

|

|

Export

Packing

|

1,700

x 2,100 x 2,180 mm (L x W x H)

|

|