|

MODEL

|

Capacity

|

Converyor

Width

|

Electrical

Power

|

Outside

Dimensions

|

|

APWT-600

|

7,000~9,000

Bottles/hr.

|

600

|

3.1

KW

|

1,000x1,550x,2,850

|

|

APWT-300

|

7,000~9,000

Bottles/hr.

|

310

|

2.9

KW

|

710x1,550x2,850

|

|

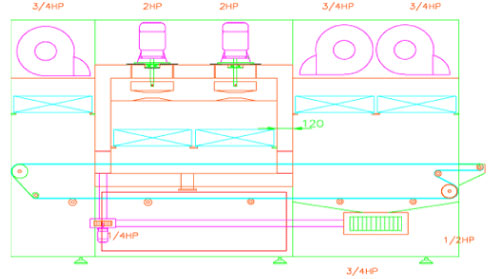

MODEL

|

Capacity

(Bottles/hr.) |

Converyor

Width |

Heater

|

Total

Electrical

Power |

Outside

Dimensions

(WxHxL) |

|

APST-900

|

10,000~12,000

|

900

mm

|

43

KW

|

46

KW

|

1,630x2,170x6,700

mm

|

|

APST-600

|

7,000~9,000

|

600

mm

|

36

KW

|

39

KW

|

1,330x2,170x6,700

mm

|

| APST-300 |

2,000~3,000

|

300

mm

|

18

KW

|

19.2

KW

|

910x1,900x3,300

mm

|