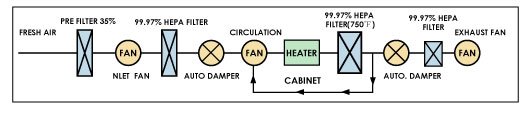

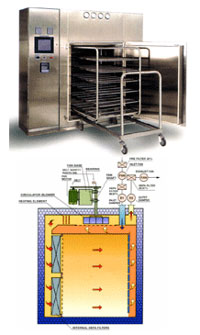

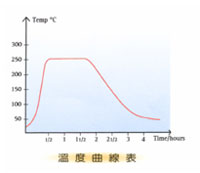

Hot air sterilizer machinery designed according to forced convection principle with fast hot-air transmission circulation, and then through HEPA FILTER ensures the chamber air class within 100. When hot air temperature up to 170°C~260°C then reduce temperature the chamberr inside the bottle, appliance, aluminum cover and rubber stopper (Low temp.) completed non germ and in according with the cGMP requlations. Before the machine leave the factory finish whole testing. Provide equipment IQ & OQ data manual, and all instruments calibrating report such as sheet document, contain varied kind of gauge and temperature sensor, provide original CALIBRATION document, correspondence with cGMP requirement.

Apply to pharmaceutical / electronics / chemical / foods etc. Mainly use for glass metal sterilizer and hot source effective. Such as vial, ampoule, injection bottles, aluminum cover etc.

Hot air sterilizer system use human machine interface touch screen (LCD with color) and PLC sequence controller easy to operate and maintain, operation panel can set up several type of display information, according the screen description to operate, adjust or install the machine.

|

Item

Model

|

Chamber

Dimension (WxHxD) |

External

Dimension (WxHxD) |

Heater

(KW) |

Fan

(HP) |

Max.

Temp

(°C) |

|

ECHS-15

|

850x1000x1000

|

2000x2100x1350

|

15

|

1

|

280

|

|

ECHS-18

|

850x1200x1000

|

2000x2300x1350

|

18

|

2

|

280

|

|

ECHS-24

|

850x1500x1000

|

2000x2600x1350

|

24

|

2

|

280

|

|

ECHS-30

|

1000x1650x1220

|

2150x2750x1570

|

30

|

3

|

280

|

|

ECHS-36

|

1200x1650x1220

|

2350x2750x1570

|

36

|

3

|

280

|

|

ECHS-45

|

1600x1650x3000

|

2750x2750x1300

|

45

|

5

|

280

|